Ribbon Mixer

Livestock feed consists of a number of ingredients, each having their own nutritional value to the animals. Uniformity in feed is a must to satisfy overall nutritional requirements of livestock to ach ieve optimum growth, good health, meet regulatory guidelines and improve FCR(Feed Conversion Ratio).

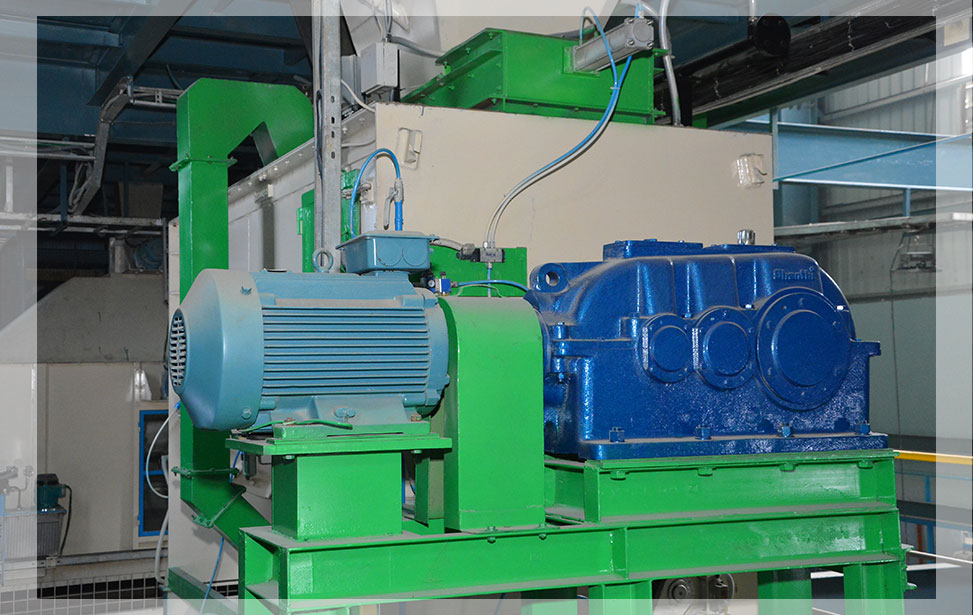

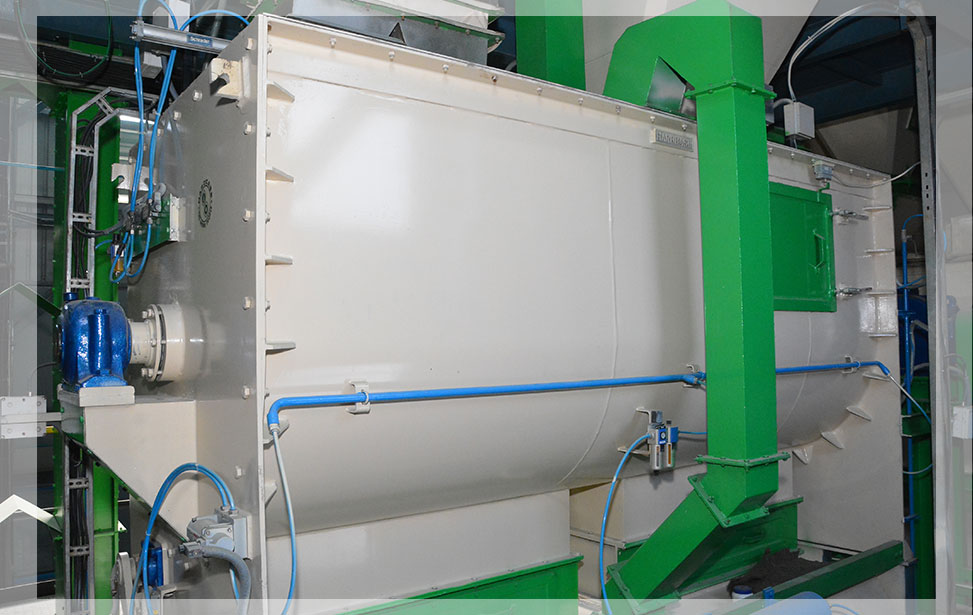

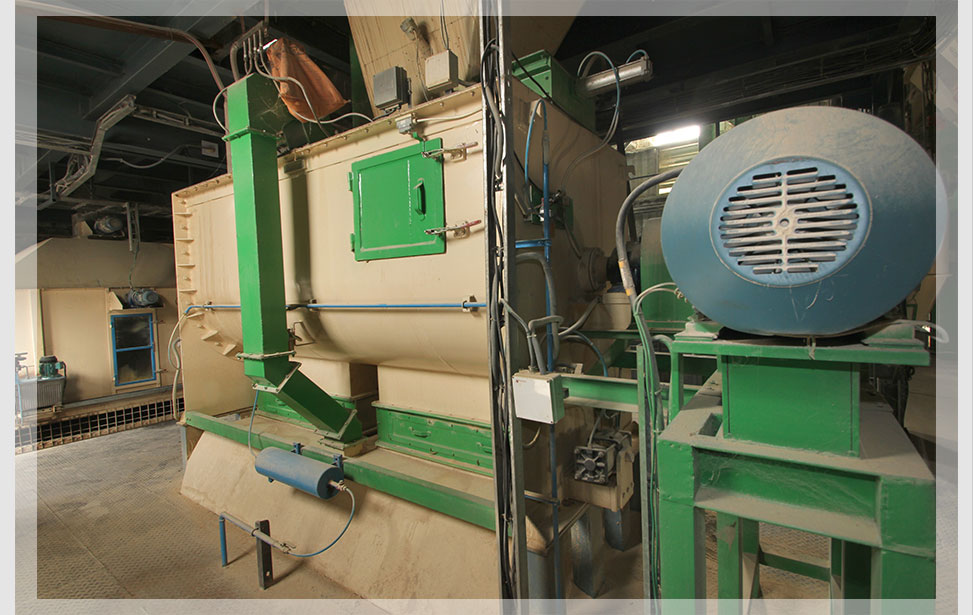

Durably constructed in either mild steel or stainless steel Hardcase Horizontal mixers ensure accurate mixing of all types of products from fine powdered materials to coarse ground ingredients to achieve the desired CV.

These mixers consists of a U shaped horizontal trough in which two helical ribbons configured in opposing directions are arranged to achieve homogenous mixing of ingredients.

Our Works

Product Photos

Features Of Ribbon Mixer

- Delivers an excellent CV

- Designed to eliminate dead spots

- Efficient Mixing cycle of 3-4 mins

- Direct coupled, Chain and gear drive possible.

- Large inspection / Cleaning doors for easy maintenance with safety switches.

- Variable frequency drive (VFD)* to enable starting of the machine on load, in case of an unscheduled power outage.

- Efficient emptying through full length discharge outlets.

- Addition of liquid constituents possible through PLC controlled dosing or manual system.

Hammer Mill Model(For Mash)

| S.no | Model | Working Volume (Litres) | Drive | Capacity per Batch* |

|---|---|---|---|---|

| 1 | HDRB - 50 | 50 | 1 HP (0.75 KW) | 25 Kgs. |

| 2 | HDRB – 100 | 100 | 1 HP (0.75 KW) | 50 Kgs |

| 3 | HDRB – 300 | 300 | 3 HP (2.2 KW) | 150 Kgs |

| 4 | HDRB – 600 | 600 | 5 HP (3.7 KW) | 300 Kgs |

| 5 | HDRB -1000 | 1000 | 7.5 HP (5.5 KW) | 500 Kgs |

| 6 | HDRB – 1400 | 1400 | 10 HP / 15 HP (7.5 KW / 11 KW) | 750 Kgs |

| 7 | HDRB - 2200 | 2200 | 20 HP / 25 HP(15KW / 18.5 KW) | 1000 Kgs |

| 8 | HDRB – 3300 | 3300 | 25 HP / 30 HP(18.5 KW / 22 KW) | 1500 Kgs |

| 8 | HDRB - 4400 | 4400 | 30 HP / 22 KW | 2000 Kgs |

*capacity is based on Bilk density of 0.55 tons/cu. mtrs.

Our Clients