Weighing, Proportioning & Packing

From storage to the end product, accurate weighing is an integral part of a successful plants operation. The right mix and formulation of all macro, micro and liquid ingredients is of utmost importance for the production of quality feed specially as the complexity of ingredients and volume of production increases.

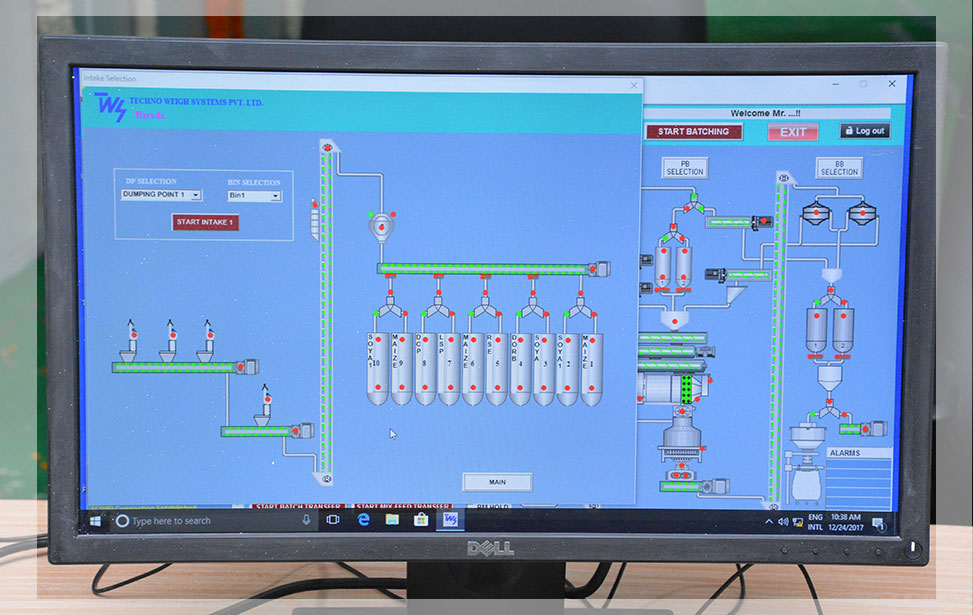

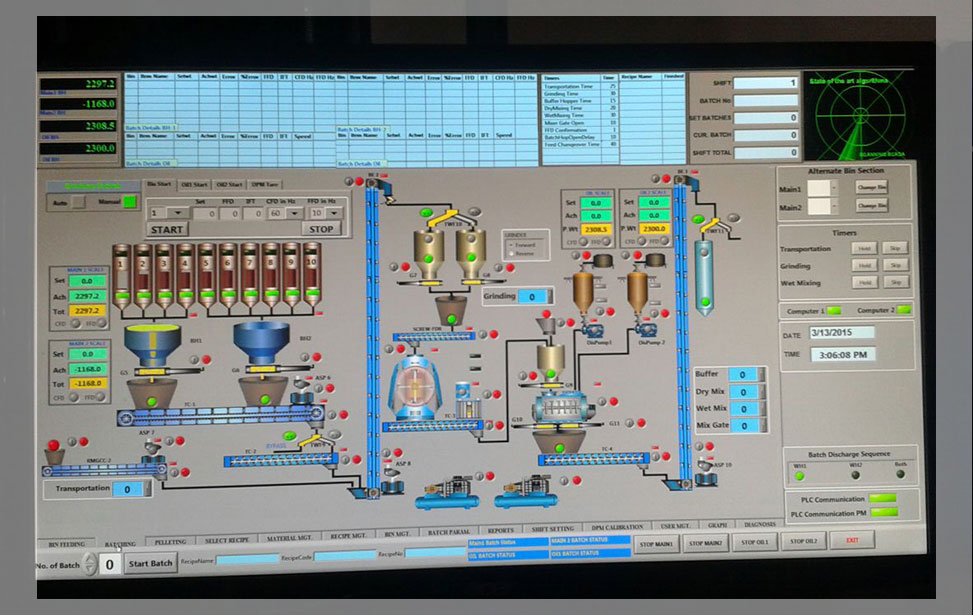

In the macro batching system ingredients are weighed and released from storage bins into the production process via a sophisticated weighing and proportioning system. It generally consist of storage bins with scales below to weigh ingredients, controlled by a sophisticated PLC based SCADA system.

Micro weighting technology takes proportioning and dosing to a higher level of accuracy for valuable micro ingredients such as vitamins, additives and trace elements. The micro proportioning system weighs and each micro ingredient accurately such that the exact amount in mixed into the product batch during the mixing cycle. We also offer automatic liquid proportioning and dosing for accurate addition of liquids, fats, oils and molasses incorporated in to the mixing cycle.

Our Works

Product Photos

Features of Weighing and Proportioning systems

- Flexible formula composition

- High weigh accuracy

- PLC controlled semi or fully automatic process

Process Automation

Hardcase provides automation for different sizes of feed processing operation. These systems are provided as basic control systems for the control of each individual machine or complete automated systems to control entire process lines. They ensure consistent feed quality and cost effective processing. Plants provided with integrated automation systems provide traceability of ingredients and monitoring of all process parameters.

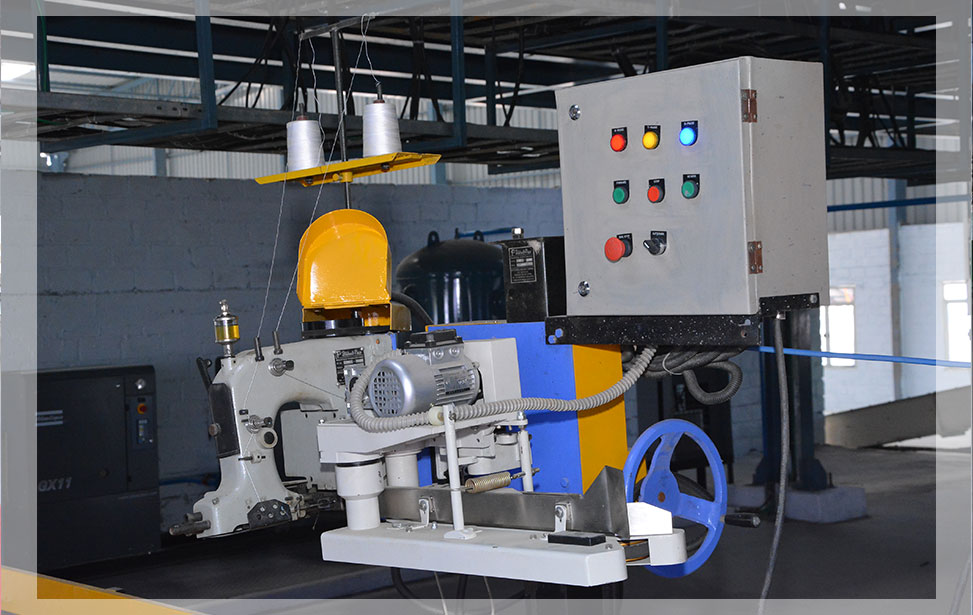

Packing

Hardcase provides a wide range of packing solutions with different levels of automation and design.

Our Clients